rockwell hardness test experiment manual|rockwell hardness testing guide pdf : member club Hardness Test 1/5 LAB 2 HARDNESS TEST OBJECTIVES (1) Make Brinell, Vickers and Rockwell hardness measurements on different materials specimens. (2) Compare the .

Resultado da Name: 🇧🇷 TS Anne Ganzarolli 🇧🇷🔝 . Username: anneganzarolli . Profile URL: anneganzarolli . Location: João Pessoa, Brazil, South America. Price: .

{plog:ftitle_list}

WEB最近、Instagramで、ストーリーズをあげたら、エロアカウントに、ストーリーズいいねをされます。これは僕だけじゃないですよね?最近、そういうのが増えているのでしょ .

rockwell hardness testing instructions

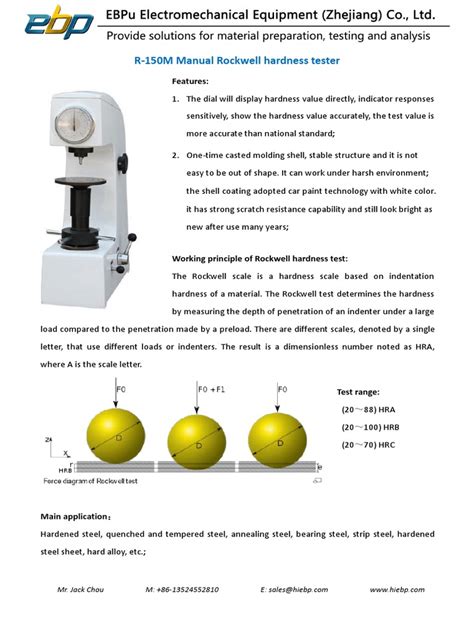

The hardness of a material by this Rockwell hardness test method is measured by the depth of Penetration of the indenter. The depth of Penetration is inversely

The hardness test is a mechanical test for material properties which are used in engineering design, analysis of structures and material development. The hardness test is performed to . The Rockwell hardness is derived from the measurement of the depth of the impression EP = Depth of penetration due to Minor load of 98.07 N. Ea = Increase in depth of .Experiment No. 1 ROCKWELL HARDNESS TEST Aim: To determine the Rockwell hardness for hard materials such as hardened steel & moderately hard materials such as brass. .

what are the differences in charpy and izod impact test

rockwell hardness testing guide pdf

This experiment provides fundamental knowledge on hardness of materials, hardness test procedure, hardness testing types, hardness testing machine, hardness of different metal .

Hardness Test 1/5 LAB 2 HARDNESS TEST OBJECTIVES (1) Make Brinell, Vickers and Rockwell hardness measurements on different materials specimens. (2) Compare the .The Rockwell test is based on measurement of the depth of penetration with the hardness number read directly from the dial gauge or digital display that is part of every tester. In .Scope* 1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials, including test methods for the .Figure 3. Rockwell Hardness Tesing Schematic. There are 30 different Rockwell scales, defined by the combination of the indenter and minor and major loads. The majority of .

Rockwell hardness tester presents direct reading of hardness number on a dial provided with the machine. Principally this testing is similar to brinell hardness testing. It differs only in diameter and material of the indenter and the applied .

TO DETERMINE IMPACT STRENGTH OF STEELBY CHARPY TEST AIM: To determined impact strength of steel. OBJECT: To determine the impact strength of steel by Charpy test APPARATUS: 1. Impact testing machine 2. A steel specimen 10 mm X 10mm X 55mm THEORY: An impact test signifies toughness of material that is ability of material toRockwell hardness test is applied with the carbide balls to test softer materials such as construction steels or brass because if you test soft material with diamond cones, it could cause very deep penetration into the material which will go far outside from the specified depth of 0.2mm. With a carbide ball, the specified reference depth is .Definition of the Rockwell hardness test method The Rockwell hardness test methods are described by a number of scales, characterized by a standard, an indenter type, and a load. Examples of Rockwell hardness test methods: .

7. SPECIFICATION OF HARDNESS TESTING MACHINE AND INDENTERS A hardness test can be conducted on Brinell hardness testing machine, Rockwell hardness machine or Vicker hardness testing machine. The specimen may be a cylinder, cube, thick or thin metallic sheet. A Rockwell hardness testing machine along with the specimen is shown in Figure 2.Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .LAB MANUAL STRENGTH OF MATERIAL. 2 LIST OF EXPERIMENTS . Rockwell hardness test. 20 . 3 EXPERIMENT NO.1 TITLE: TENSION TEST AIM: To determine the tensile strength of specimen . EXPERIMENT NO.3 TITLE: TORSION TEST AIM: To find the modulus of rigidity. SPECIMEN AND EQUIPMENTS 1. A torsion testing apparatus,

what are the possible impacts of less-than-thorough testing

Rockwell hardness testing machine series Versatile smart models 3 models to suit practically every application Features Specifications External dimensions (512) 434 65 218 352.4 162 150 13 780 . Manual Maximum specimen dimensions Height 180 mm (100 mm if the cover is attached), depth 165 mm (from indenter axis to the frame)

Rockwell hardness test: Rockwell hardness test with the method of measuring pressure depth, hardness value through instructions direct reading, therefore, simple and convenient operation, easy to grasp, high efficiency, suitable for batch parts inspection; Rockwell hardness test method, can use diamond indenter and

the surface of the test piece is approximately 1/8” to 1/16” from the tip of the indenter. 3. Press the StArt key to initiate a test cycle 4. the display will count down to “0” (See keypad section of manual to adjust time-at-load). 5. When the test is complete, the .

EXPERIMENT NO. – 01 AIM :- To study the Brinell Hardness testing machine and the Brinell hardness test. APPARATUS: - Brinell Hardness testing machine, specimen of mild steel / cast iron/ non ferrous metals and Brinell microscope. THEORY: - Hardness represents the resistance of material surface to abrasion, scratching and cutting, hardness after gives clear identification .Specimens of various metals (aluminium, brass, copper, high speed steel in this experiment) Indenters Rockwell hardness testing machine (b)Theory There are many de nitions for hardness depending on the material. For metals, the most appropriate one would be ‘resistance to permanent deformation’. Hardness can bethe test result will be displayed. If the test result exceeds a tolerance setting, the test result will be preceded by a blinking “H” or “L” for high or low result. 6. To take a second test, the handwheel must be turned counter-clockwise to lower the in-denter from the test specimen before another test can be taken. ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for metallic materials. ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness .

A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). [1] There are different scales, denoted by a single letter, that use different loads or indenters.LABORATORY MANUAL II Year B. Tech II- Semester MECHANICAL ENGINEERING STRENGTH OF MATERIALS LAB R18A0383. . Rockwell hardness test Note: Total 10 Experiments are to be conducted Course Outcomes: 1. Analyse and design structural members subjected to tension, compression, torsion, . EXPERIMENT No. 1 TENSION TEST AIM: .

Phase II Hardness Testers accurately measure hardness of materials in Rockwell hardness A, B, and C scales. Heat-treated steels are tested using a 120° diamond indentor in the C-scale (HRC 20-70). Soft materials are tested using a 1/16" carbide ball indenter in the B-scale (HRB 25-100). Very hard materials are tested using a 120° diamondRockwell hardness of hard alloy, quenched and unquenched steels in the labs of research institutions, colleges, factories and mines. 2. Principle of Test Rockwell hardness test is to apply diamond cone indenter (see Fig-2) or steel ball indenter (see Fig-3) to the specimen surface in two steps as shown in Fig-1, which shall1. To study the Brinell hardness testing machine & perform the Brinell hardness test. 2. To study the Rockwell hardness testing machine & perform the Rockwell hardness test. 3. To study the Vickers hardness testing machine & perform the Vickers hardness test. 4. To study the Erichsen sheet metal testing machine & perform the Erichsen sheet .

EXPERIMENT - 3 BRINELL HARDNESS TEST Objective: To determine the hardness of a given material by Brinell's hardness testing machine. Equipment: Brinell's hardness testing machine, microscope and specimen General theory for hardness test: Hardness may be defined as resistance of the metal plastic deformation by indentation.Rockwell hardness differs from Brinell hardness testing in that the indentation size is measured in Brinell testing while Rockwell hardness is determined by the depth of the indentation made by a constant applied load. For thin test samples or samples for which the relatively large Brinell or Rockwell indentations must beThe Rockwell method is a static hardness testing method, which can be further characterised as follows: It is one of the standardised procedures (ISO 6508, ASTM E18).Digital Rockwell Hardness Tester Instruction Manual 21 Industrial Ave • Upper Saddle River, NJ. 07458 Tel: (201)962-7373 • Fax: (201)962-8353 . Figure 5.1.1 is the typical display of Rockwell C testing parameter; showing the current scale, indenter type, test force, load dwell, as well as current date and time. .

The Rockwell hardness test is a indentation hardness test in which a diamond cone having an included angle of 120o and radius of curvature at the tip of 0.2mm, or a hardened steel or hard metal ball having a diameter of 1.5875mm for B, F, G and all 'T' scales or 3.175 mm for E, H and K scales are used.The indenter is forced into the surface of a test piece in two steps, initially a .TWIN Rockwell Hardness Tester Model No. 3815 Operation Manual Technical Support Tel: (201)962-8352 . E. 5 Rockwell Test Blocks 1. Two each, HRC 2. One each, HRB 3. Two each, HRN 4. One each, HRT . Operating Instructions & Parts Manual Page 9 ) (HRC) Hardness .

The Rockwell hardness test is one of several common indentation hardness tests used today, other . Power Supply Battery Battery Manual/110v Output to PC Yes Yes Some Models Type Model Model Dynamic Testers PHT-2000D PHT-2500D Ultrasonic (UCI) MET-U1 MET-UD . Rockwell 900-331 &

This experiment was carried out in our university lab to determine hardness of metallic materials using Rockwell Hardness test Discover the world's research 25+ million membersII. Theory and Principle of the Rockwell Hardness Test. The Rockwell Hardness Test uses a depth-differential method to test for hardness. A predetermined minor load is applied to the test sample, and the depth measurement is taken. Then a major load is applied to the same spot, which creates a deeper indentation.

rockwell hardness testing chart

web28 de jul. de 2022 · https://fapello.com/anitta/ https://fapello.com/mc-mirella/ https://fapello.com/vanessa-vailatti/ https://fapello.com/juliana-bonde/ .

rockwell hardness test experiment manual|rockwell hardness testing guide pdf